The Gantry System Misconceptions That Are Costing You Time Without Aluminum Framing

Gantry systems are the backbone of many industrial and automation setups, yet outdated assumptions often hold companies back from making smarter choices. Many still believe that heavy steel is the only reliable option, or that modular designs can’t meet precision requirements. These misconceptions waste time, money, and efficiency. It’s time to separate fact from fiction and rethink the role of aluminum framing in gantry systems.

Heavy Steel Frames Are the Only Option for Strength and Stability

For decades, steel has been the go-to material for gantry systems, largely due to the belief that it’s the only way to achieve strength and stability. While steel is undeniably strong, it’s also unnecessarily heavy, expensive, and difficult to modify. Aluminum framing offers an equally durable alternative without the excessive weight, making it easier to transport, install, and adjust when needed.

In industrial environments, strength is about engineering, not just material weight. Aluminum framing, when properly designed, can support heavy loads without the added strain on structural components. Its high strength-to-weight ratio allows for better load distribution while reducing the stress on motors, actuators, and other moving parts. This translates to smoother operation, less wear and tear, and ultimately longer-lasting performance.

Gantry Systems Must Be Custom-Fabricated Every Time

The assumption that every gantry system must be built from scratch leads to unnecessary delays and inflated costs. Traditional steel structures often require full custom fabrication, with welding, machining, and reinforcement at every stage. This not only takes time but also demands skilled labor, making modifications a costly and time-consuming process.

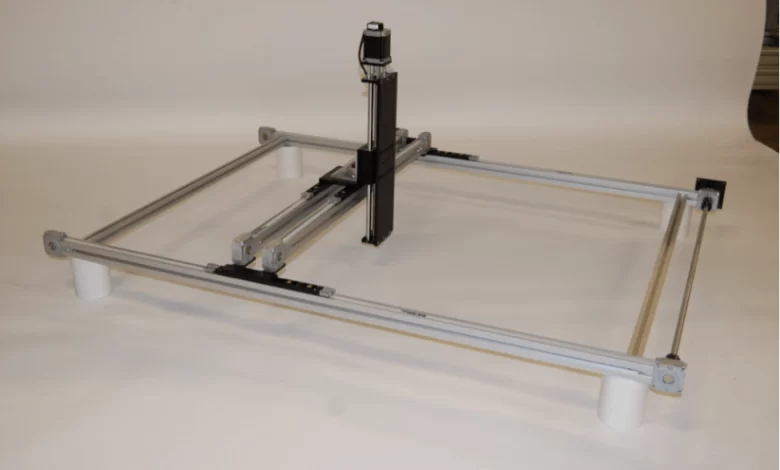

Aluminum framing eliminates these roadblocks by offering a modular approach. Pre-engineered components can be assembled quickly, adjusted on-site, and expanded as needed. Instead of waiting weeks for a custom steel frame, teams can configure an aluminum gantry system in a fraction of the time. The flexibility of aluminum framing means adjustments can be made without dismantling the entire structure, keeping projects on schedule and within budget.

Aluminum Can’t Handle High Loads in Industrial Settings

One of the biggest myths about aluminum framing is that it lacks the strength to support heavy industrial loads. In reality, aluminum’s structural integrity is more than capable of handling demanding applications when designed correctly. Aerospace, automotive, and robotics industries all rely on aluminum for high-load applications, proving that its capabilities extend far beyond lightweight designs.

The key lies in engineering and load distribution. Aluminum gantry systems use reinforced extrusions and strategic bracing to handle significant weight while reducing overall system stress. Additionally, aluminum is naturally corrosion-resistant, meaning it won’t degrade over time like untreated steel. This makes it a more reliable option for industries where exposure to moisture, chemicals, or extreme temperatures is a concern.

Assembly and Adjustments Require Expensive Specialized Tools

Steel gantry systems often demand specialized tools, welding equipment, and skilled labor for both assembly and modifications. This leads to higher costs and longer project timelines, especially when adjustments are needed after installation. Many assume aluminum framing comes with similar challenges, but the reality is quite different.

Aluminum gantry systems use T-slot extrusion technology, allowing components to be connected with simple fasteners instead of welded joints. Adjustments can be made with standard hand tools, eliminating the need for heavy machinery or specialized training. Whether reconfiguring an existing setup or making last-minute design changes, aluminum framing provides a level of flexibility that steel simply cannot match.

Modular Designs Are Too Weak for Precision Applications

Precision machinery demands stability, and many believe that modular aluminum gantry systems can’t provide the necessary rigidity. This misconception comes from outdated designs that lacked proper reinforcement. Today’s aluminum framing solutions are engineered with precision in mind, incorporating high-tolerance components and rigid connections that rival welded steel structures.

The adaptability of aluminum framing allows for fine-tuned adjustments without sacrificing accuracy. In applications like CNC machining, automated assembly lines, and material handling, aluminum gantries deliver the precision required while offering the added benefit of easy customization. With proper bracing and anchoring techniques, modular systems perform just as well—if not better—than their rigid steel counterparts.

Steel Gantry Systems Last Longer Than Aluminum Ones

Durability is always a concern in industrial environments, and many assume steel is the superior long-term choice. While steel is strong, it’s also prone to rust, oxidation, and fatigue over time. Without proper coatings or maintenance, steel gantry systems degrade faster than expected, requiring costly repairs or replacements.

Aluminum framing, on the other hand, is naturally resistant to corrosion. It maintains its structural integrity without the need for heavy protective coatings, making it ideal for harsh environments. Additionally, aluminum’s lightweight properties reduce mechanical stress on supporting structures and moving parts, leading to less wear and a longer service life. Properly engineered aluminum gantries outlast steel alternatives while offering lower maintenance requirements and greater adaptability.