Printed Circuit Board Assembly: A Comprehensive Guide!

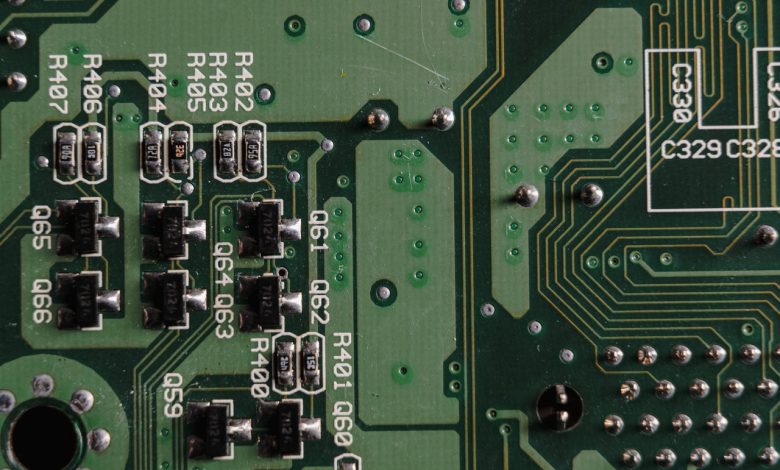

Printed circuit board assembly (component mounting) is a process that requires the use of highly specialized equipment and a lot of experience. It is here that the parts of the printed circuit board come together, and the PCB gets its functionality.

The circuit board consists of several layers, each one with a specific function. The bottom layer is the foundation of the PCB and contains patterns of copper tracks that connect various points, called pads, on the board. The copper tracks use to carry signals between different components.

The first layer (or two) is used to insulate the copper tracks from each other so that they do not interfere with each other. The rest of the layers are used for connecting components to each other and for routing signals between them.

PCB Assembly is the process of mounting components on a PCB. The process is not as easy as it sounds. It requires a lot of expertise and professionals to do the job well.

There are several steps in printed circuit board assembly:

- Fabrication of Printed Circuit Board

- Parts Procurement

- Surface Mount Technology or Through Hole Technology

- Electrical Testing and Inspection

There are many steps in the process of circuit board assembly, and many factors to consider when choosing a contract manufacturer. If you don’t know what to look for, it can be difficult to compare companies. In this post, we’ll help you understand what criteria are important and why. We’ll also illustrate the differences between turnkey and partial-turnkey assembly.

What is turnkey PCB assembly?

A turnkey PCB assembly company will supply all of the parts required for your project, including components that may not be directly related to electronics, like screws, washers, and standoffs. These companies may also provide box build services which include the cost of enclosure materials in addition to labor costs. This option is typically more expensive than partial-turnkey PCB assembly because you don’t have to source any components or enclosures yourself. However, turnkey is more convenient because everything is handled by one company.

What is partial-turnkey PCB assembly?

Partial-turnkey printed circuit board assembly means that a contract manufacturer will supply some parts for your project and you will supply others. You can choose which parts you want to provide yourself based on your budget and availability. Partial-turnkey is generally less expensive because you will only pay for supplied parts.

Choosing the right company

There are numerous factors that you should take into account when choosing the right company. No doubt, your selection of the company can make a big difference in your end product.

Quality Assurance and Control Processes

One of the most important things to ensure when choosing an assembling company is whether it has a quality assurance and control process in place. You need to be sure that the materials used for your circuit boards are of high quality and are correctly assembled. If you take your time to search for an ideal company, then you will find one that uses high-quality materials and also has a strict quality control process in place. This will give you peace of mind knowing that your circuit boards will work as they should without any problems.

Cost

The cost of your circuit boards is also something you should consider when choosing a company. Make sure the company you are planning to hire should not strain your wallet. Get in touch with a few companies and compare prices.

Customer Service

Find out how well the customer service of your potential company is. Call and email them and find out how quickly and satisfactorily they respond to your queries.